Introduction

We are finally in the Caribbean and enjoying the tropical island life after 4 years in the Mediterranean. It is certainly a different way of life and definitely a much easier place to sit in your aft cockpit and enjoy a sundowner at anchor. Not to say we didn’t enjoy the Mediterranean but you really can live quite easily on anchor without ever having to visit a marina here in the Caribbean.

The Touristy Stuff

After 18 days spent crossing the Atlantic Ocean from Las Palmas in the Canary Islands to St Lucia, we were up for a well earned break from the boat. After clearance in at Rodney Bay we slowly made our way down the St Lucian coast to Soufriere to enjoy the sights. We had our first experience with Boat Boys. Many of the islands have what they call boat boys who visit the anchored boats and offer all manner of services including selling fresh fruit and vegetables, freshly caught fish and providing mooring buoy and tour services. We met one of the boat boys of Soufriere who organised our stay including mooring fees and a full day tour of the town. We visited the Botanical Gardens, many waterfallls (both cold and hot) the volcanic crater which was still active and bubbling mud and swimming in the hot pools nearby. The best part of the day was when Malcolm took the kids for a quick ride to the Pitons. The Pitons are an iconic part of St Lucia’s coastline. They are two volcanic plugs sitting right on the water’s edge. The clear water, coral and sea life along this part of the coastline is spectacular.

Inspecting the Hull

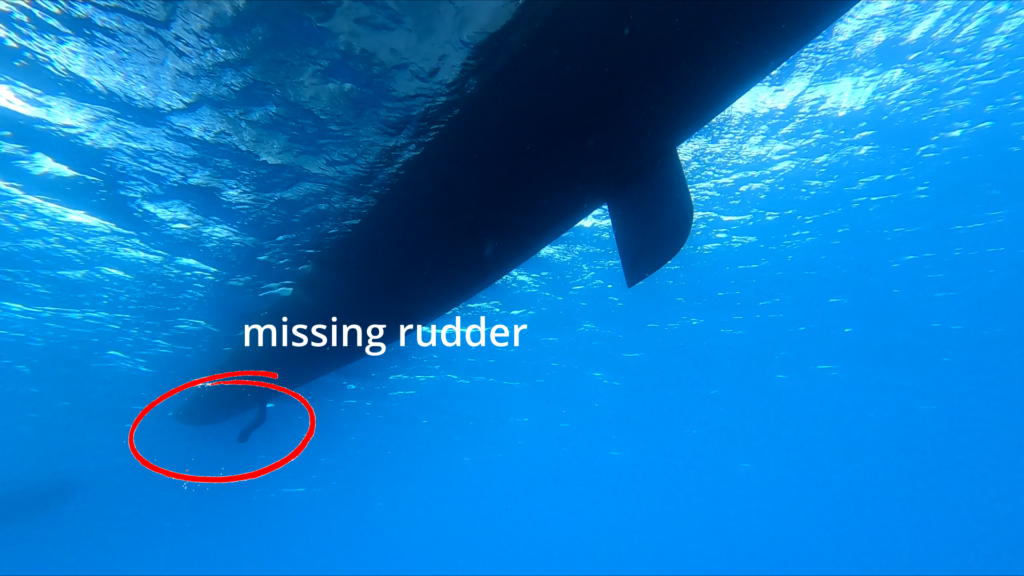

After we had a chance to explore the island and enjoy a bit of family time, it was time to dive into the water and inspect the hull. We hadn’t managed to have a good look at the hull since we lost the rudder in the middle of the Atlantic Ocean. From the GoPro footage we took, there didn’t appear to be any serious issues apart from the absence of one rudder but we needed to know what happened and were hoping we could find some clues as to what went wrong.

What did we find?

Our observations are as follows: There were 2 failure points evident on the stainless steel stock. These rusty looking spots on the tube wall are evidence of micro cracking. The arrow shows the part of the stock where the break is not as clean. This area is rough and ragged and shows where the rudder was still attached before it was ripped away. In the lower part of the picture there are scratch marks in the hull where the rudder and shaft would have scraped along the hull as it broke away and left the boat.

What happened to our Rudder

Based on the evidence we found we can safely assume that the 2 points of failure caused the rudder stock to break. These micro cracks were not evident at the time we fitted the new blades in Valencia and it is important to note that we have sailed over 3000nm since then and these cracks could have happened at any stage. The rust around the cracks is indicating the age of the cracks much like rings on the trunk of a tree.

You can also see in the picture that the right side of the stock has bent upwards where the stock pulled and ripped away with the rudder. The scratch marks on the hull indicate where the rudder bumped along the hull as it left the boat.

Are our new rudders to blame?

Possibly! The biggest difference between our old and new rudders was their location in relation to the hull. The old rudders had quite a large gap between the rudder and the hull whereas the new ones were fitted as close as possible to the hull. The new rudders create a hydrodynamic seal and help increase lift. This would have most certainly placed more load on our thin walled stainless steel tube. Given the fact that this tube was already compromised by the micro cracking we saw earlier, it is no surprise the shaft failed and we lost our rudder.

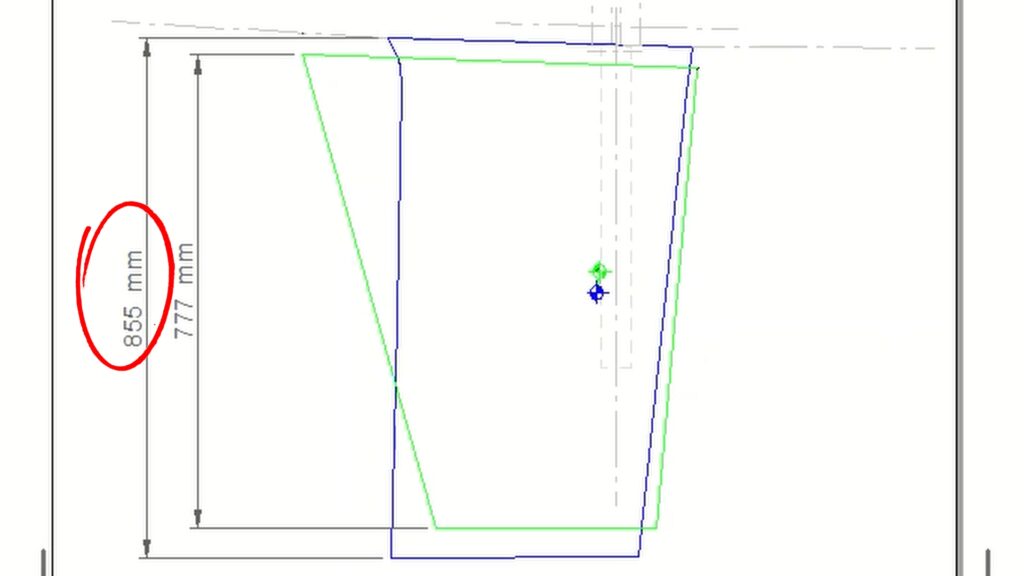

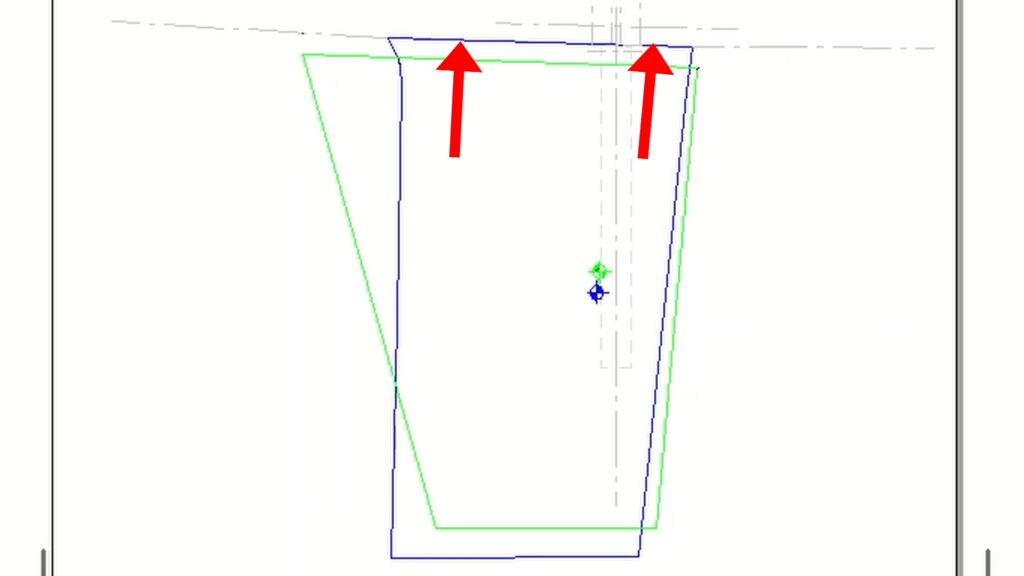

Differences between the old and new rudders

The old rudder is shown here in green, while the new rudder is shown in blue. You can see the new rudder is 855mm in total length, it is 35mm bigger at the top and 50mm bigger at the bottom. While the new blue rudder is not greatly bigger than the previous rudders, it is a higher aspect ratio. The higher the aspect ratio, the more lift is generated.

The placement of the new rudders was critical to ensure efficiency. We made the rudders fit close to the hull to ensure maximum lift. The hydrodynamic seal created by fitting the rudders closer to the hull means that the water cannot flow over the top of the rudder and therefore allowing more surface area to generate lift.

What’s next?

We have been collecting a lot of data while sailing over the last few years and because we have information on the 2 different rudders, we can compare each. We will use this information to design a new set of rudders for Paikea. They may or may not involve winglets. We shall run through the designs of each to see which one performs best. We will design our own carbon rudder stock tube and get it delivered to us here in the Caribbean. Then we will be able to build the blades for the rudder stock on the boat.